Maintaining hydraulic pumps and motors

Sep 13, 2024

Maintaining hydraulic pumps and motors is crucial because they are the core components of hydraulic systems, driving the movement and force necessary for the system’s operation. Proper maintenance ensures that these components function efficiently and reliably, reducing the risk of breakdowns and extending their lifespan. Here’s a detailed guide on maintaining hydraulic pumps and motors:

Comprehensive Guide to Maintaining Hydraulic Pumps and Motors

Hydraulic pumps and motors are the heart of hydraulic systems, converting mechanical energy into hydraulic energy and vice versa. Ensuring their proper maintenance is essential for the overall performance and longevity of the hydraulic system.

1. Understanding Hydraulic Pumps and Motors

- Hydraulic Pumps: These devices convert mechanical energy into hydraulic energy by moving fluid through the system. Common types include gear pumps, vane pumps, and piston pumps.

- Hydraulic Motors: These convert hydraulic energy back into mechanical energy to drive various types of machinery and components. They can be radial piston, axial piston, gear, or vane motors.

2. Regular Maintenance Practices

a. Inspect and Replace Hydraulic Fluid

- Importance: Hydraulic fluid lubricates and cools the components, and its quality affects pump and motor performance.

- Action: Check the fluid level and condition regularly. Replace the fluid according to the manufacturer’s recommendations or when it becomes contaminated or degraded.

b. Check for Leaks

- Importance: Leaks can reduce system efficiency and lead to fluid loss.

- Action: Inspect pumps, motors, and associated hoses for signs of leaks. Address any leaks promptly by tightening connections, replacing seals, or repairing damaged components.

c. Monitor Fluid Temperature

- Importance: Excessive heat can degrade hydraulic fluid and damage components.

- Action: Ensure that the hydraulic system operates within the recommended temperature range. Use cooling systems or heat exchangers if necessary to maintain proper fluid temperatures.

d. Clean or Replace Filters

- Importance: Filters remove contaminants from hydraulic fluid, preventing damage to pumps and motors.

- Action: Check and clean or replace filters regularly. Follow the manufacturer’s guidelines for filter maintenance to ensure proper fluid cleanliness.

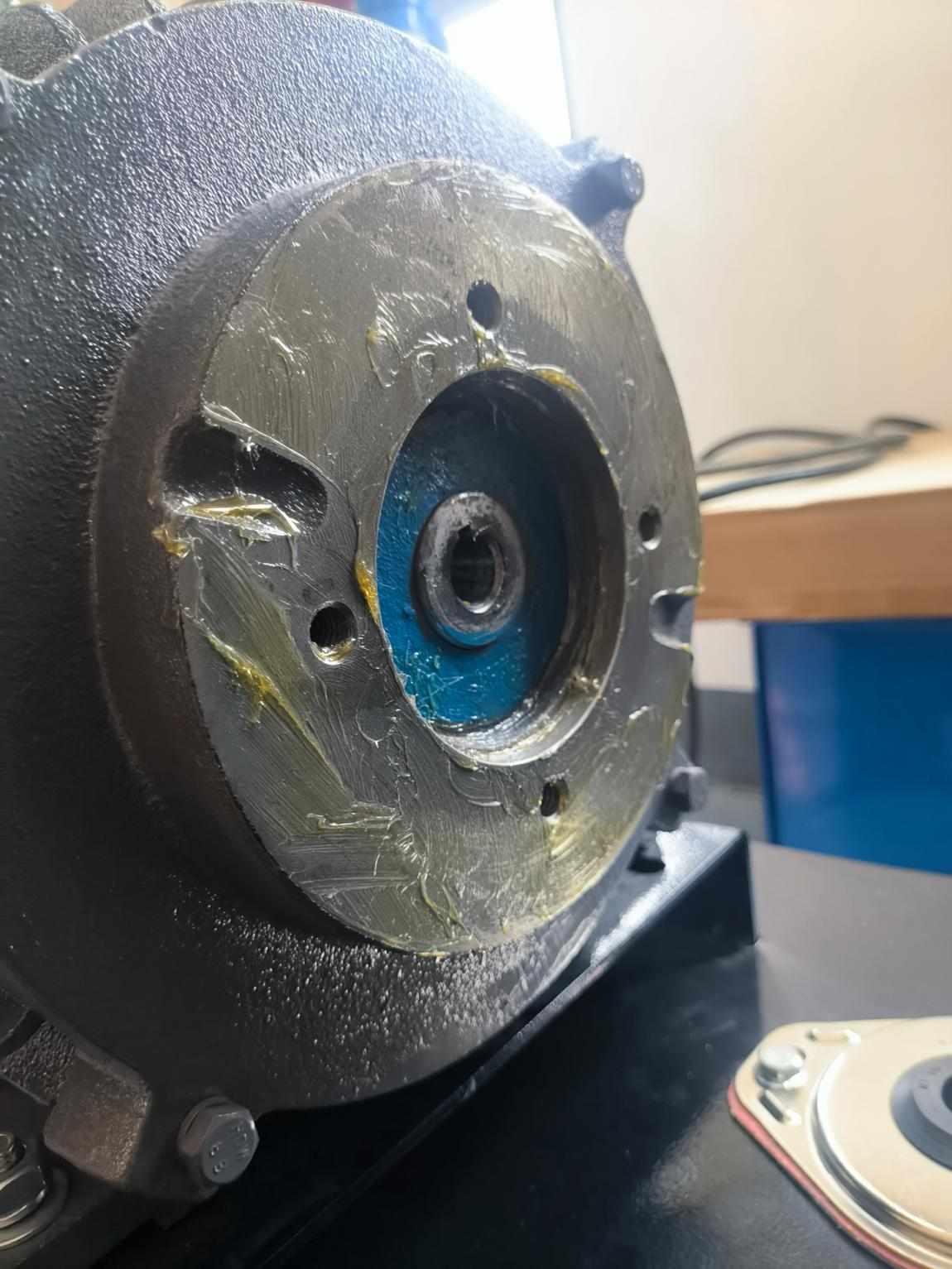

e. Inspect and Maintain Pump and Motor Components

- Importance: Wear and tear on internal components can affect performance and lead to failures.

- Action: Regularly inspect components such as bearings, shafts, and seals for wear. Replace any worn or damaged parts and ensure all components are properly lubricated.

f. Check System Pressure

- Importance: Correct system pressure is crucial for efficient operation and preventing damage.

- Action: Use a pressure gauge to measure and verify system pressure. Adjust pressure settings or check the pressure relief valve to ensure it is within the recommended range.

g. Lubricate Moving Parts

- Importance: Proper lubrication reduces friction and wear on moving parts.

- Action: Apply lubricant to moving parts of the pumps and motors as per the manufacturer’s specifications. Use the recommended type and amount of lubricant.

h. Ensure Proper Alignment

- Importance: Misalignment can cause excessive wear and damage to pumps and motors.

- Action: Check and ensure that pumps and motors are properly aligned with their drives and connected components. Realign if necessary to prevent operational issues.

i. Listen for Unusual Noises

- Importance: Unusual noises can indicate internal problems or wear.

- Action: Pay attention to any abnormal sounds such as grinding, whining, or knocking. Investigate and address the source of the noise to prevent further damage.

j. Perform System Diagnostics

- Importance: Regular diagnostics can help detect issues before they become major problems.

- Action: Use diagnostic tools to monitor system performance and detect potential issues. Regularly review data such as pressure, flow rate, and temperature.

3. Troubleshooting Common Problems

a. Low Pressure

- Symptoms: Reduced force or movement, sluggish operation.

- Causes: Possible causes include leaks, clogged filters, or a malfunctioning pump.

- Solutions: Inspect for leaks, clean or replace filters, and check pump operation.

b. Excessive Noise

- Symptoms: Loud or abnormal sounds from the pump or motor.

- Causes: Worn bearings, cavitation, or misalignment.

- Solutions: Check for wear, ensure proper alignment, and investigate cavitation issues.

c. Overheating

- Symptoms: High fluid temperature, potential system shutdowns.

- Causes: Inadequate cooling, high fluid viscosity, or overloading.

- Solutions: Improve cooling, check fluid viscosity, and ensure the system is not overloaded.

d. Erratic Operation

- Symptoms: Inconsistent performance or movement.

- Causes: Air in the system, worn components, or variable pressure.

- Solutions: Bleed the system, inspect and replace worn parts, and check pressure settings.

4. Preventive Maintenance Tips

- Create a Maintenance Schedule: Develop and follow a regular maintenance schedule for inspecting and servicing hydraulic pumps and motors.

- Keep Records: Maintain detailed records of maintenance activities, including inspections, replacements, and repairs.

- Training: Ensure that personnel are properly trained in hydraulic system maintenance and troubleshooting.

5. When to Seek Professional Help

- Complex Issues: For issues beyond basic maintenance, such as severe component failures or advanced diagnostic needs, consult a hydraulic specialist.

- Specialized Equipment: Professional technicians can provide advanced diagnostic tools and expertise to address complex problems.

HCIC is a professional hydraulic manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, commissioning and hydraulic components brand sales and technical services science 1998. During these years we develop our engineer team and quality control team,make sure providing safe and reliable products. We hope that our product can help to save your cost and improve your quality. For More details please email us "[email protected]" or Google search "HCIC hydraulic"

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA